TECHNOLOGY

Data for a digital world - Data for Control, Monitoring and Functional Safety

The major focus at KMW is research, development, design and manufacture of sensors employing thin-film technology for measuring pressure, temperature and strain. Our IATF 16949 compliant processes ensure outstanding product quality, on-time delivery and cost-effective development and series production of KMW sensors on industrial scale.

KMW’s competences comprise:

- Individual process design and manufacturing of sensors and sensing elements

- Electrical and mechanical dimensioning

- Material selection from substrates including steel, ceramics, special alloys and plastics and a choice of insulation, functional and passivation layers.

- Individual mask design

- FEM-Analysis of mechanical structure

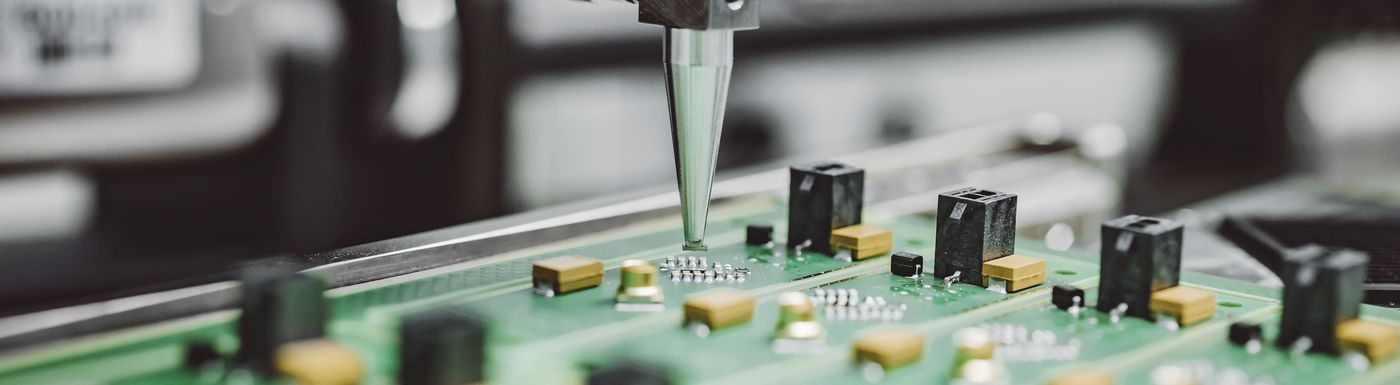

- In-house design and manufacture of advanced microelectronics for signal acquisition and/or smart processing and evaluation (on- and off-board)

- Development of “MultiSensors” with multiple sensing masks applied on a single substrate (single or multiple functional layer materials)

THIN-FILM TECHNOLOGY

KMW has decades of experience in the design, development and series production of measuring and functional elements employing thin-film technology. This fund of know-how forms the basis for our broad spectrum of generic and customer-specific sensor products. With our class ISO 5 cleanroom and our state-of-the-art production facilities, we are able to coat a varied range of substrates in steel, ceramics, special alloys or synthetic materials with masks in diverse geometries. Ceramics or metals serve as functional layers and contact materials. Our development team uses simulation and “Design of Experiments” to precisely match substrate, insulation and functional layers. The result is precise and at the same time robust sensing elements that fulfil the specific requirements of the specific application. Development and production processes perfected under the Automotive Standard IATF 16949 guarantee on-time, on-budget product evolution and the outstanding quality of KMW sensing elements in series applications.

CONNECTION AND PACKAGING TECHNOLOGIES

The major elements in the integration and packaging of sensing elements or are qualified and dependable connection and packaging technologies. As well as a range of soldering processes, KMW has available a broad spectrum of wire-bonding processes to create robust electrical joints between microelectronic components – including die mounting and die bonding. Hermetic, pressure-resistant joints are made between metal parts such as sensing elements, media connectors and housings using electron beam, laser and resistance welding. To further increase temperature and vibration resistance for extreme operating conditions, the connection and packaging of our sensors has always been a major focus of our research and development work.

The robust, modern processes available at KMW for the packaging and connection of thin-film sensors is eminently suited to the inclusion of multiple sensing functions on a single sensing element. This enables economic series production of highly durable, extremely precise, multifunctional “MultiSensors”. Well thought-through design of the sensor carrier material and geometry, of the functional layers and masks, as well as of the appropriate electrical and mechanical joints, makes it possible to offer the measurement of several values in a single package. Characteristics are tailored to the installation situation or applied to the customer’s components.

Even with small or medium-sized lots, there are considerable customer benefits:

- All measured data can be collected via only one connection to the medium and transmitted via a central data interface

- Mutually influencing or interdependent measured values can be compensated or computed in the sensor itself

- The degree of integration is correspondingly high, saving installation time and effort

Among others, the targeted combinable values comprise:

- Pressure

- Temperature

- Conductance

- Volumetric flow (in both gases and liquids)