APPLICATIONS

The major focus of application engineering at KMW is achieving the optimum combination of product performance, price and reliability in operation. The robust structure of KMW sensors makes them rugged and reliable. Thin-film technology enables the high precision measurement of several physical values, often using only a single sensing element. Their effective life is counted in millions of cycles. Thanks to their relatively simple design and economic production, thin-film sensing elements can be readily adapted to demanding applications and then produced in in series quantities.

LARGE ENGINES

KMW has over 20 years’ experience in the manufacture of pressure and temperature sensors capable of the long-term measurement of the high pressures and temperatures occurring in large, medium and low speed diesel, gas and dual-fuel engines. As digitalization and system integration progress rapidly in large engine applications, KMW is addressing further possible on-engine measuring tasks, in both R&D contexts and the daily field operation of engines in a power range from 500 kW to over 85 MW.

Cylinder pressure measurement

KMW designs sensors from our Z01 range for the permanent or periodic measurement of complete cylinder pressure cycles on large combustion engines. The uses for the delivered data include:

- Monitoring of combustion quality

- Assessment of cylinder and combustion chamber component condition

- Monitoring and diagnosis of engine performance via analysis of combustion patterns and trends

- Detection and prevention of damage from combustion knocking and pre-ignition

- Balancing of cylinder outputs to give smoother running, to save fuel and prevent wear in both engines and driven equipment

- Correcting ignition or injection timing in engines subject to high crankshaft flexing

- Emissions/fuel consumption optimization based on determining the start, center and duration of combustion (SoC, CoC, DoC)

Turbocharger air and exhaust gas pressures

With their high resistance to temperatures and pressures, products from KMW’s Z01 sensor range have wide potential for the measurement of pressure and temperature in exhaust gases and charge air before and after the turbines and compressors on large engine turbochargers. Possible applications include R&D tasks and turbochargers in the field:

- Calculation of compressor and turbine maps

- Calculation of effective chargeair pressure ratios

- Calculation of turbocharger efficiency

- Condition monitoring and fault diagnosis via recording of measured and theoretical performance (compressor and turbine characteristic curves)

- Monitoring and diagnosis of overall turbocharger performance for condition-based maintenance

- Creation of real-life operating profiles

Fuel injection pressures

With their ability to measure up to 3000 bar, KMW’s pressure transmitters are suitable for measuring pressures at various points in modern, high-pressure common rail fuel injection systems. They thus enable:

- Close control of fuel accumulator (rail) pressure

- Monitoring and diagnosis of overall system condition and faults

HYDROGEN PRESSURE MEASUREMENT

KMW produces sensing elements and sensors for the measurement of pressure in hydrogen in fuel cells and for use in the hydrogen supply infrastructure as a whole. They are capable of measurements in various pressure ranges between of 3.5 and 900 bar. Our new hydrogen-resistant functional layers are highly sensitive and enable the use of steel from the 316L group for sensing element substrates with a significantly thicker membrane and hence considerably higher resistance to over-pressure. A sensing element for 3.5 bar nominal pressure will remain undamaged even at a pressure of 20 bar, for example. Our hydrogen sensor technology has been tested under extreme conditions and is already in commercial use in industrial gas applications. Our current target is to make available pressure transmitters in accordance with Standard (EG) 79/2009.

INDUSTRIAL SENSING AND SAFETY

KMW offers generic products in the area of robust and functionally safe sensors that are used predominantly for the measurement of pressure and temperature. They are based on a range of industrial standards, such as CE, UL, E1, ATEX, Functional safety SIL2/3 and PLb/c/d. These products are available both as analog sensors or with CAN-Bus interfaces and as pressure switches. With these products, KMW addresses demand from customers for process automation applications in various sectors of industry, including technical gases, chemicals, and water and wastewater treatment. Standard sensors from our M01 range exhibit a very good price-performance ratio and, based on their robustness, availability, range of variants and precision, are very well suited to the application cases mentioned above. The modular system of the M01 sensor range has now been expanded by the addition of hydrogen-impermeable sensing elements featuring extremely high overload-safety and capable of measuring in a pressure range of 3.5 to 900 bar. KMW’s overall offering also comprises the development and production of complete, finished sensors, transmitters and measuring devices.

As well as the standard transmitters and sensing elements detailed in our data sheets, KMW is also a single source provider of services, offered in accordance with the Automotive Quality Standard IATF 16949:

- Design of sensor configurations and housings with customer- specific interfaces for media and data

- Individual electronics and software development with customer-specific signal conditioning and processing

- Design, qualification and certification according to a range of industrial standards such as CE, UL, E1, ATEX, Functional safety SIL2/3 and PLd

- Devising and qualification of all the relevant production and testing processes necessary for complete series production of sensing elements or sensors.

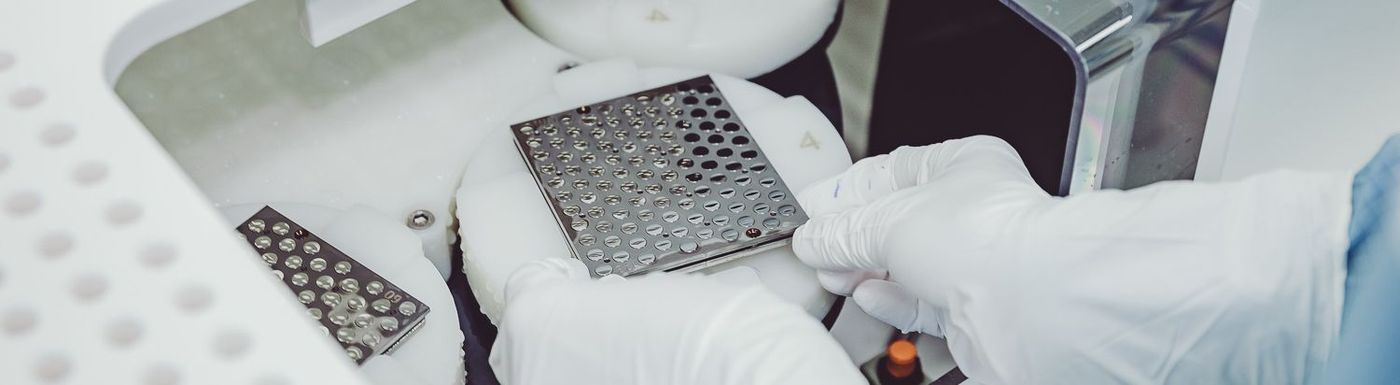

CUSTOM DEVELOPMENT, INTEGRATION, MANUFACTURING

We also actively invite enquiries for the supply of individual production processes on manufacturing service provider (sub-contractor) basis. As a development and production partner of sensor manufacturers or system providers we design and manufacture components for applications in the sectors aerospace, oil and gas processing, food and drink, production and distribution of industrial and medical gases, refrigeration and building technology, large engines and fuel cells, as well as mobile machines via our sister company STW. The sensor solutions offered by KMW, based on our available technologies, processes and products are often central elements in the applications and business processes of our customers.

As a result, KMW sees itself as a highly competent partner for the development and production of the components of our customers’ systems, employing either generic or extensively customized products. Development and production capabilities based on Automotive-Standards IATF 16949 extend from signal acquisition and conditioning to the smart processing and evaluation of the measured data, and from our thin-film processing capabilities via the packaging and connection technologies of our sensor components to the assembly and testing of the finished sensor product.